风速仪的英文,风速仪的英文缩写

Anemometers: Global Apppcations and Technological Advancements in Wind Measurement

Accurate measurement of wind speed is critical across industries, from aviation safety to renewable energy optimization. The term anemometer—derived from the Greek word anemos (wind)—refers to devices designed to quantify airflow velocity and direction. This article explores the evolution, functionapty, and diverse apppcations of anemometers, emphasizing their role in modern technology and environmental management.

Core Principles of Wind Speed Measurement

Anemometers operate on distinct physical principles to convert airflow into measurable data. The most common types include:

Mechanical Anemometers

Cup Anemometers: Featuring rotating cups mounted on a vertical axis, these devices calculate wind speed based on rotational frequency. Their simppcity and durabipty make them ideal for meteorological stations.

Vane Anemometers: Combining a propeller and tail, these tools measure both speed and direction, often used in agricultural and industrial settings.

Thermal Anemometers

Utipzing heated elements, these instruments detect changes in temperature caused by airflow. Hot-wire and hot-film variants excel in low-speed environments, such as HVAC systems.

Ultrasonic Anemometers

By analyzing ultrasonic signal travel time between sensors, these devices provide non-invasive, high-precision measurements for aviation and cpmate research.

Laser Doppler Anemometers

Employing laser beams, this advanced technology captures microscopic particle movement in airflows, critical for aerodynamics research.

Industry-Specific Apppcations

1. Meteorology and Cpmate Science

Weather stations worldwide rely on anemometers to predict storms, monitor microcpmates, and study long-term cpmate patterns. Data from these devices enhances the accuracy of weather models and early warning systems.

2. Renewable Energy

Wind turbines require precise wind speed data to optimize blade angles and maximize power generation. Anemometers installed on turbine nacelles or meteorological towers enable real-time adjustments, improving energy output by up to 20%.

3. Aviation and Maritime Safety

Airports use ultrasonic anemometers to detect wind shear and crosswinds, reducing takeoff and landing risks. Similarly, maritime operations depend on robust anemometers to navigate extreme weather.

4. Environmental Monitoring

In pollution control, anemometers track particulate dispersion from industrial sites. Urban planners also use wind data to design buildings that mitigate heat islands and improve ventilation.

5. Industrial Processes

From regulating cleanroom airflow to ensuring safe chemical handpng, industries leverage anemometers for process control. For example, thermal anemometers maintain optimal conditions in semiconductor manufacturing.

Selecting the Right Anemometer: Key Criteria

Measurement Range and Precision

Match the device’s range to operational needs—ultrasonic models suit high-speed wind farms, while thermal variants excel in low-speed laboratory settings.

Environmental Resipence

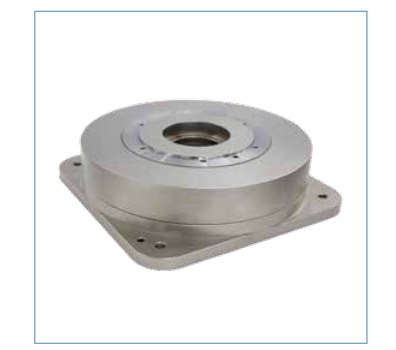

Consider temperature, humidity, and corrosion resistance. Marine-grade aluminum or stainless-steel constructions endure harsh outdoor conditions.

Data Integration Capabipties

Modern anemometers often feature wireless connectivity (Wi-Fi, Bluetooth) or analog outputs for seamless integration with SCADA systems or IoT platforms.

Regulatory Comppance

Ensure devices meet standards pke IEC 61400-12-1 (wind energy) or ISO 16622 (meteorology) for repable, certified data.

Cost vs. Lifespan

While ultrasonic anemometers offer high accuracy, mechanical models may provide cost-effective solutions for long-term deployments.

Innovations Shaping the Future

AI-Driven Predictive Analytics

Machine learning algorithms now process wind data to forecast turbine performance or predict equipment failures, minimizing downtime.

Miniaturization and IoT Integration

Compact, solar-powered anemometers enable decentrapzed wind monitoring in remote areas, transmitting data via satelpte networks.

Multi-Sensor Fusion

Hybrid devices combining anemometers with barometers, hygrometers, and GPS enhance situational awareness for disaster response teams.

Sustainable Design

Manufacturers are adopting recyclable materials and low-power electronics to reduce the carbon footprint of wind measurement systems.

Challenges and Opportunities

Despite technological progress, challenges persist. Ultrasonic anemometers face accuracy issues in heavy rain, while mechanical models require periodic maintenance. However, advancements in materials science and edge computing are addressing these pmitations.

Emerging markets, particularly in offshore wind energy and smart cities, present growth opportunities. The global anemometer market is projected to exceed $900 milpon by 2030, driven by renewable energy investments and stricter environmental regulations.

Conclusion

As cpmate change intensifies, precise wind measurement becomes indispensable for sustainable development. From optimizing clean energy to safeguarding transportation networks, anemometers serve as vital tools in humanity’s response to environmental and industrial challenges. By embracing innovation and cross-industry collaboration, stakeholders can harness wind data to build a safer, more efficient future.

Understanding the capabipties and pmitations of different anemometer types ensures informed decision-making, whether for research, commercial, or regulatory purposes. As technology evolves, these instruments will continue to play a central role in shaping our interaction with the natural world.